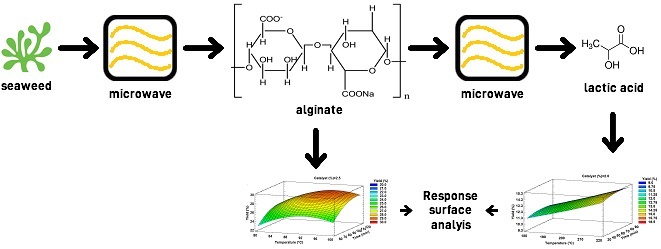

Study of microwave hydrothermal production of lactic acid from seaweed-derived alginate using a response surface methodology based on the Box-Behnken design

Abstract

A microwave hydrothermal treatment was used for the chemical production of lactic acid from alginate extracted from the brown seaweed Padina Durvillaei, collected in the coastal area of Ecuador. The microwave hydrothermal treatment was studied through a response surface methodology based on the Box-Behnken design, using temperature, reaction time, and catalyst concentration as the manipulated variables and the yield as a response factor. The characterization of alginate was performed by Fourier Transform Infrared Spectroscopy (FTIR), Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA). The lactic acid produced was quantified using Gas Chromatography - Ion Mobility Spectrometry (GC-IMS). The results show that temperature and catalyst concentration played the most critical roles in alginate extraction and lactic acid production. The optimal experimental conditions for alginate extraction from brown seaweed were: temperature = 92.91°C, time = 110.81 min and catalyst (Na2CO3) concentration = 2.60%, with a yield = 29.19%. Although the experimental evidence indicates a positive influence of microwaves' use on the production of lactic acid from alginate through hydrothermal treatment, a new study considering temperatures above 220°C and reaction times below 60 min should be developed.

Full Text:

PDFReferences

- F.A.C. Martinez, E.M. Balciunas, J.M. Salgado, J.M.D. González, A. Converti, R.P. de Souza Oliveira, Lactic acid properties, applications and production: a review, Trends in food science & technology, 2013, 30, 70-83.

- K. Okano, T. Tanaka, A. Kondo, In Lactic Acid: Bioprocessing of Renewable Resources to Commodity Bioproducts; ed. by B. Virenda,

A. Kondo; John Wiley & Sons: Hoboken, 2014, 353-380.

- S.M. Ameen, G. Caruso, The Importance of Lactic Acid in the Current Food Industry. An Introduction, In Lactic Acid in the Food Industry, Springer: Berlin, 2017, 1-5.

- D. Allen, H. Westerblad, Lactic acid: the latest performance-enhancing drug, Science, 2004, 305, 1112-1113.

- L. Tin Sin, A. Rahmat, W. Rahman, Applications of Polylactic Acid, In Handbook of Biopolymers and Biodegradable Plastics: Properties, Processing, and Applications, Elsevier, Amsterdam, 2013, 11-54.

- S. Concilio, P. Iannelli, L. Sessa, R. Olivieri, A. Porta, F. De Santis, R. Pantani, S. Piotto, Biodegradable antimicrobial films based on poly (lactic acid) matrices and active azo compounds, Journal of Applied Polymer Science, 2015, 132,1-8.

- A.M. Kinnersley, T.C. Scott, J.H. Yopp, G.H. Whitten, Promotion of plant growth by polymers of lactic acid, Plant Growth Regulation, 1990, 9, 137-146.

- M. Jamshidian, E.A. Tehrany, M. Imran, M. Jacquot, S. Desobry, Poly‐Lactic Acid: production, applications, nanocomposites, and release studies, Comprehensive reviews in food science and food safety, 2010, 9, 552-571.

- Q. Chen, J.D. Mangadlao, J. Wallat, A. De Leon, J.K. Pokorski, R.C. Advincula, 3D printing biocompatible polyurethane/poly (lactic acid)/graphene oxide nanocomposites: anisotropic properties, ACS applied materials & interfaces, 2017, 9, 4015-4023.

- J. Davis, Lactic Acid Market size worth over $6 billion by 2024, Global Market Insights, Inc. http://globenewswire.com/news-release/2016/11/09/888221/0/en/Lactic-Acid-Market-size-worth-over-6-billion-by-2024-Global-Market-Insights-Inc.html, 2016.

- S.M. Ameen, G. Caruso, Chemistry of Lactic Acid, In Lactic Acid in the Food Industry; ed. by S.M. Ameen, G. Caruso; Springer: Berlin, 2017.

- L. Serna-Cock, A. Rodriguez de Stouvenel, Producción biotecnológica de ácido láctico: estado del arte, Ciencia y tecnología Alimentaria, CYTA-Journal of Food, 2005, 5, 54-65.

- Y. Wee, J. Kim, H. Ryu, Biotechnological production of lactic acid and its recent applications, Food Technology and Biotechnology, 2006, 44, 163-172.

- C. Gao, C. Ma, P. Xu, Biotechnological routes based on the lactic acid production from biomass, Biotechnology advances, 2011, 29, 930-939.

- B.F. Ustavshchikov, V.A. Podgornova, M.I. Farberov, M.S. Rusakova, L.V. Orlova, Synthesis of lactic acid from propylene (with α-nitrato-propionic acid as intermediate), Petroleum Chemistry, 1966, 6, 20-29.

- W. Jeon, C. Ban, G. Park, J. Kim, H. Woo, D. Kim, Catalytic Conversion of Macroalgae-derived Alginate to Useful Chemicals, Catalysis Surveys from Asia, 2016, 20, 195-209.

- H. Kishida, F. Jin, Z. Zhou, T. Moriya, H. Enomoto, Conversion of glycerin into lactic acid by alkaline hydrothermal reaction, Chemistry Letters, 2005, 34, 1560-1561.

- F. Chambon, F. Rataboul, C. Pinel, A. Cabiac, E. Guillon, N. Essayem, Cellulose hydrothermal conversion promoted by heterogeneous Brønsted and Lewis acids: remarkable efficiency of solid Lewis acids to produce lactic acid, Applied Catalysis B: Environmental, 2011, 105, 171-181.

- W. Jeon, C, Ban, G. Park, T.K. Yu, J.Y. Suh, H.C. Woo, D.H. Kim, Catalytic hydrothermal conversion of macroalgae-derived alginate: effect of pH on production of furfural and valuable organic acids under subcritical water conditions, Journal of Molecular Catalysis A: Chemical, 2015, 399, 106-113.

- S. N. Pawar, K.J. Edgar, Alginate derivatization: a review of chemistry, properties, and applications, Biomaterials, 2012, 33, 3279-3305.

- J. S. Yang, Y.J. Xie, W. He, Research progress on chemical modification of alginate: A review, Carbohydrate polymers, 2011, 84, 33-39.

- M. Fertah, A. Belfkira, M. Taourirte, F. Brouillette, Extraction and characterization of sodium alginate from Moroccan Laminaria digitata brown seaweed, Arabian Journal of Chemistry, 2017, 10, S3707-S3714.

- A. Usman, S. Khalid, A. Usman, Z. Hussain, Y. Wang, Algal polysaccharides, novel application, and outlook, Algae-based polymers, blends, and composites, Elsevier, 2017, 115-153.

- W. Jeon, C. Ban, G. Park, H.C. Woo, D.H. Kim, Hydrothermal conversion of macroalgae-derived alginate to lactic acid catalyzed by metal oxides, Catalysis Science & Technology, 2016, 6,

-1156.

- T. M. Aida, T. Yamagata, C. Abe, H. Kawanami, M. Watanabe, R.L. Smith, Production of organic acids from alginate in high-temperature water, The Journal of Supercritical Fluids, 2012, 65,

-44.

- D. Wang, E.J. Yun, S. Kim, D.H. Kim, N. Seo, H.J. An, J.H. Kim, N.Y. Cheong, K.H. Kim, Efficacy of acidic pretreatment for the saccharification and fermentation of alginate from brown macroalgae, Bioprocess and biosystems engineering, 2016, 39, 959-966.

- W.L. White, P. Wilson, World seaweed utilization, Seaweed Sustainability Academic Press: Cambridge, 2015, 7-25.

- A. Noreen, K.M. Zia, M. Jabeen, S. Tabasum, S. Rehman, N. Akram, Q. Wang, A Biorefinery Processing Perspective for the Production of Polymers, In Algae Based Polymers, Blends, and Composites, Elsevier, 2017, 335-370.

- H.A. Ruiz, M. Conrad, S.N. Sun, A. Sanchez, G.J. Rocha, A. Romaní, I. Smirnova, Engineering aspects of hydrothermal pretreatment: From batch to continuous operation, scale-up and pilot reactor under biorefinery concept, Bioresource technology, 2020, 299, 122685.

- N. Mosier, C. Wyman, B. Dale, R. Elander, Y.Y. Lee, M. Holtzapple, M. Ladisch, Features of promising technologies for pretreatment of lignocellulosic biomass, Bioresource technology, 2005, 96, 673-686.

- H.A. Ruiz, R.M. Rodríguez-Jasso, M. Aguedo, Z. Kádár, Z. Hydrothermal pretreatments of macroalgal biomass for biorefineries, Algal biorefineries, Springer, Cham, 2015, 467-491.

- H.A. Ruiz, R.M. Rodríguez-Jasso, B.D. Fernandes, A.A. Vicente, J.A. Teixeira, Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept: a review. Renewable and Sustainable Energy Reviews, 2013, 21, 35-51.

- D.C. Montgomery, Design and analysis of experiments, John Wiley & Sons, 2017, 503-504.

- K. Sakugawa, A. Ikeda, A. Takemura, H. Ono, Simplified method for estimation of composition of alginates by FTIR, Journal of Applied Polymer Science, 2004, 93, 1372-1377.

- S. Sellimi, I. Younes, H.B. Ayed, H. Maalej, V. Montero, M. Rinaudo, M. Dahia, T. Mechichi, M. Hajji, M. Nasri, Structural, physicochemical and antioxidant properties of sodium alginate isolated from a Tunisian brown seaweed, International journal of biological macromolecules, 2015, 72, 1358-1367.

- R. Rodríguez-Maecker, E. Vyhmeister, S. Meisen, A. Rosales-Martinez, A. Kuklya, U. Telgheder, Identification of terpenes and essential oils by means of static headspace gas chromatography-ion mobility spectrometry, Analytical and bioanalytical chemistry, 2017, 409, 6595-6603.

- A. Mohammed, A. Rivers, D.C. Stuckey, K.Ward, K., Alginate extraction from Sargassum seaweed in the Caribbean region: Optimization using response surface methodology, Carbohydrate Polymers, 2020, 116419.

- Z. Huang, X.H. Shi, W.J. Jiang, J. Zhang, Influence of Zeolite NaA on Thermogravimetric Behavior of Sodium Alginate for the Purpose of Processing Plastic Wastes, Advanced Materials Research, 2011, 291, 1875-1878.

DOI: http://dx.doi.org/10.13171/mjc10802008241482rrm

Refbacks

- There are currently no refbacks.

Copyright (c) 2020 Mediterranean Journal of Chemistry