Production of ceramic tiles by combining Moroccan phosphate mine tailings with abundant local clays

Abstract

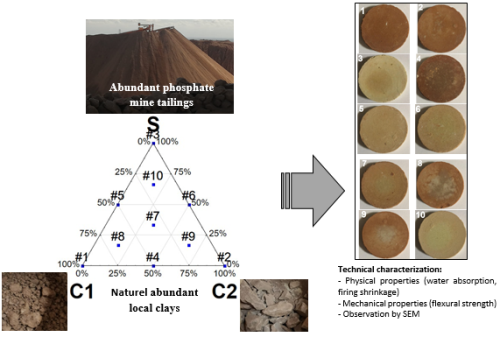

This study offers an easy, economical, and ecological solution to manufacture a ceramic faience product with excellent mechanical properties by combining Moroccan phosphate mine tailings and two abundant local clays. The use of these clays alone was inconceivable because they do not generate a material that meets the mechanical requirements.

A mixture design strategy conducted the optimization of the formulation. Therefore, ten tests were carried out. The ceramic tiles produced are characterized by their physical properties (water absorption, shrinkage), mechanical properties (flexural strength), and surface properties (observation by scanning electron microscopy).

The results show that phosphate mine tailings improve the mechanical properties of ceramic tiles. Industrial use at a rate of 33% in formulas based on abundant local clays could, therefore, be envisaged to design faience products, conforming to the mechanical and technical requirements. This mode of production contributes to saving non-renewable natural resources, preserving the environment, and aligns with the principle of sustainable development.

Full Text:

PDFReferences

- R. Hakkou, M. Benzaazoua, B. Bussière, Acid mine drainage at the abandoned Kettaramine (Morocco): 2. Mine waste geochemical behaviour, Mine Water and the Environment, 2008, 27, 160-170.

- R. Hakkou, M. Benzaazoua, B. Bussière, Laboratory Evaluation of the Use of Alkaline Phosphate Wastes for the Control of Acidic Mine Drainage, Mine Water and the Environment, 2009, 28, 206-218.

- R. Hakkou, M. Benzaazoua, B. Bussière, Valorization of phosphate waste rocks and sludge from the Moroccan phosphate mines: Challenges and perspectives, Procedia Engineering, 2016, 138, 110-118.

- F. Boutaleb, N. Boutaleb, B. Bahlaouan, S. Deblij, S. El Antri, Effect of Phosphate Mine Tailings from Morocco on the Mechanical Properties of Ceramic Tiles, International Journal of Engineering Researc&Technology, 2020, 9, 140-145.

- F. Boutaleb, N. Boutaleb, B. Bahlaouan, S. El Antri, Valorisation du stérile d’exploitation des phosphates au Maroc dans la fabrication de carreaux céramiques, Techniques Sciences Méthodes, 2020, 2, 37-43.

- N. Bardet, N. E. Jalil, F. de Lapparent de Broin, D. Germain, O. Lambert, M. Amaghzaz, A Giant Chelonioid Turtle from the Late Cretaceous of Morocco with a Suction Feeding Apparatus Unique among Tetrapods, PLoS One, 2013, 8, 1-10.

- J. Yans, M. Amaghzaz, B. Bouya, H. Cappetta, P. Iacumin, L. Kocsis, M. Mouflih, O. Selloum, S. Sen, Y. Storme, E. Gheerbrant, First carbon isotope chemostratigraphy of the OuledAbdoun phosphate Basin, Morocco; implications for dating and evolution of earliest African placental mammals, Gondwana Research, 2014, 25, 257–269.

- Dahir du 9 Rajab 1370 (6 avril 1951) relatif aux mines.

- Loi n ° 33.13 sur les mines, Bulletin Officiel n ° 6380 du 23 juillet 2015.

- M. Loutou, M. Hajjaji, M. Mansori, C. Favotto, R. Hakkou, Phosphate sludge: Thermal transformation and use as lightweight aggregate material, Journal of Environmental Management, 2013, 130, 354-360.

- H. Sfar Felfoul, M. Benouezdou, P. Clastres, Etude du phosphogypse de Sfax en vue d’une valorisation en technique routière, Colloque

« Matériaux, Sols et Structures, MS2, 2004,

-131.

- K. Boughzala, A. Jaouadi, N. Fattah, K. Bouzouita, H. Ben Hassine, Traitement et valorisation des rejets de phosphates de Gafsa Treatment and Valorization of Waste Gafsa pohosphate, Revue science des matériaux, Laboratoire LARHYSS, 2015, 4, 13-31.

- S. Moukannaa, M. Loutou, M. Benzaazoua, L. Vitola, J. Alami, R. Hakkou, Recycling of phosphate mine tailings for the production of geopolymers, J. Clean. Prod, 2018, 185, 891–903.

- A. Manni, A. Elhaddar, A. El Bouari, I. E. El Hassani, C. Sadik, Complete characterization of Berrechid clays (Morocco) and manufacturing of new ceramic using minimal amounts of feldspars: Economic implication, Case Studies in Construction Materials, 2017, 7, 144-153.

- ASTM, American Society for Testing Material, Standard Method for Particle-size analysis of Soil, D. 422-63 (Reapproved 1972) Annual Book of ASTM Standards. Part, 1974, 19, 70-80.

- ISO 17892-4 :2016, Reconnaissance et essais géotechniques — Essais de laboratoire sur les sols — Partie 4: Détermination de la distribution granulométrie des particules, 2016.

- ISO 10545-4 :2019, Carreaux et dalles céramiques — Partie 4: Détermination de la résistance à la flexion et de la force de rupture, 2019.

- ISO 10545-3 :2018, Carreaux et dalles céramiques — Partie 3: Détermination de l'absorption d'eau, de la porosité ouverte, de la densité relative apparente et de la masse volumique globale, 2018.

- J. Goupy, Pratiquer les Plans d’Expériences : Dunod. Paris, 2005, 560.

- J. Gharsalli, R. Rkik, H. Zouari, F. Turki, M. Chaabane, Composition and Ceramic Properties of Carbonate-Bearing: Illitic Clays from North-Eastern Tunisia,Verres, Céramiques& Composites, 2011, 1, 4-15.

- N. El Yakoubi, M. Aberkan, M. Ouadia, Potentialité d'utilisation d'argiles marocaines de Jbel Kharrou dans l'industrie céramique Use potentialities of Moroccan clays from the Jbel Kharrou area in the ceramic industry, Comptes Rendus Geoscience, 2006, 338, 693-702.

- ISO 13006 :2018, Carreaux et dalles céramiques — Définitions, classification, caractéristiques et marquage, 2018.

- W. Chih-Huang, L. Deng-Fong, C. Pen-Chi, Utilization of sludge as brick materials, Advances in Environmental Research, 2003, 7, 679–685.

- M. Sawadogo, L. Zerbo, M. Seynou, B. Sorgho, R. Ouedraogo, Propriétés technologiques de carreaux céramiques à base d’argiles, influence d’un talc naturel, Chemistry & Chemical Engineering, Biotechnology, Food Industry, 2014, 15, 231–238.

DOI: http://dx.doi.org/10.13171/mjc10602006221445nb

Refbacks

Copyright (c) 2020 Mediterranean Journal of Chemistry