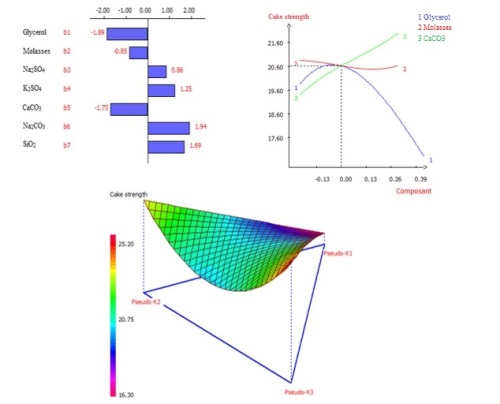

Screening and mixture design applied to formulate anti-caking compositions for reducing the caking tendency of granular phosphate fertilizers

Abstract

The demand for fertilizers in the agricultural sector has increased drastically with the world's exponential growth. Moreover, solid granular fertilizers remain by far the most requested. The granular fertilizers production presents several kinds of problems, especially the ternary fertilizers family. The caking is a severe issue that affects granules' physical quality, particularly during storage and transport. It makes them unsuitable for their intended uses. In this work, a new anti-caking agent has been developed to cope with the granular fertilizer caking problem and improve their physical quality. First of all, thanks to the screening design of Plackett-Burman, the effect of seven anti-caking components on the phosphate fertilizer caking trend was evaluated only by eight trials. Next, a mixture design was used to formulate a new anti-caking agent from three components (glycerol, calcium carbonate, and molasses). The screening design was chosen as the most effective components. Finally, from the mixture design results, a special cubic model was postulated and statically validated. The model delivered a wide range of compositions formulated from the three components mentioned above, capable of reducing the caking tendency of ternary granular fertilizer.

Full Text:

PDFReferences

- D. Turner, C. Batello, H. Dreyer, T. Calles, World fertilizer trends and outlook to 2022, FAO, Rome, 2019.

- M. Prud’homme, J. de Sousa, V. Couturier, O. Rousseau, S. Marcel-Monnier, Fertilizer outlook 2018-2022, IFA, Berlin, 2018.

- G. S. Hunter, Dry fertilizer compositions and method for making the same, U.S. Pat. Appl. 6558445 B2, 2003.

- T. M. Lowry, F. C. Hemmings, The properties of powders. Part I. The caking of salts, J. Soc. Chem. Ind., 1920, 39, 101-110.

- J. R. Adams, A. R. Merz, Hygroscopicity of fertilizer materials and mixtures, Ind. Eng. Chem., 1929, 21, 305-307.

- A. Tyc, D. Niewes, S. Penkala, R. Grzesik, K. Hoffmann, J.Hoffmann, Influence of anti-caking agents on the highly effective organic coatings for preventing the caking of ammonium nitrate fertilizers, coating, 2020, 10, 1093.

- M. Chen, S. Wu, S. Xu, B. Yu, M. Shilbayeh, Y. Liu, X. Zhu, J. Wang, J. Gong, Caking of crystals: Characterization, mechanisms and prevention, Powder Technol., 2018, 337, 51-67.

- U. Zafar, V. Vivacqua, G. Calvert, M. Ghadiri, J. A. S. Cleaver, A review of bulk powder caking, Powder Technol., 2017, 313, 389-401.

- T. Ahlnäs, T. Löfgren, T. Kankaanpää, An anti-caking agent, Eur. Pat. Appl. 0858439 B1, 2002.

- A. A. A. Bod, M. Verschuren, M. Jansen, S. Jiang, J. A. M. Meijer, W. J. P. van Enckevort, E. Vlieg, Influence of anti-caking agents on the caking of sodium chloride at the powder and two-crystal scale, Powder Technol., 2015, 277, 262-267.

- M. Schultz, C. Laschilier, R. Adams, J. Hancock, M. Johnson, K. L. Jacobson, D. Fuchs, K. Rinas, Coatings and additives containing fatty acids, salts of fatty acids, or similar compounds, for use as de-dust and/or anti-caking agents for granular products, U.S. Pat. Appl. 20160304410 A1, 2016.

- D. T. Parker, M. Ogzewalla, Z. T. Burrell, Fertilizer coating for dust control and/or anti-caking, U.S. Pat. Appl. 20190077723 A1, 2019.

- S. Gadman, J. Rodsvic, Method for coating particulate fertilizers, W.O. Pat. Appl. 9915480 A1, 1999.

- T. Löfgren, O. Grönfors, T. Ahlnäs, Method for the coating of particles, the use of a coating suspension and a coated product, Eur. Pat. Appl. 1194220 B1, 2004.

- T. Wasvik, E. F. Hansen, S. G. Snartland, Agricultural composition and conditioning agent for reducing hygroscopicity, dust formation and caking of fertilizers, W.O. Pat. Appl. 0138263 A1, 2001.

- E. F. Hansen, T. Wasvik, S. G. Snartland, Agricultural composition and conditioning agent, Eur. Pat. Appl. 1390322 B1, 2006.

- H. Hero, M. Urhonen, J. Niskala, Particulate fertilizer product, method for its preparation and use, Eur. Pat. Appl. 1861342 B1, 2014.

- S. Spence, Anti-caking and dust control coating compositions containing liquid-dispersed metallic salts of fatty acids and methods of using same, Eur. Pat. Appl. 1627865 A1, 2006.

- K. J. Wheeler, R. M. Young, G. M. Harman, M. W. Hill, Coating for improved granular fertilizer efficiency, U.S. Pat. Appl. 9938202 B2, 2018.

- X. He, J. Li, M. Chen, Y. Jin, Y. Wang, J. Li, Resistance of deliquescence and caking to enhance the effective utilization of potassium nitrate: A novel surface modification method by SDS, Powder Technol., 2019, 356, 500-507.

- A. M. M. de Laat, B. M. de Roode, T. W. L. Brooijmans, Formulation aid, U.S. Pat. Appl. 20190161814 A1, 2019.

- J. F. Ang, J. F. Pond, M. Wang, L. A. McKee, Carbonate-based anti-caking agent with reduced gas release properties, U.S. Pat. Appl. 20040109927 A1, 2004.

- R. A. Lipasek, L. S. Taylor, L. J. Mauer, Effects of anti-caking agents and relative humidity on the physical and chemical stability of powdered vitamin C, J. Food Sci., 2011, 76, 1062-1074.

- R. A. Lipasek, J. C. Ortiz, L. S. Taylor, L. J. Mauer, Effects of anti-caking agents and storage conditions on the moisture sorption, caking, and flowability of deliquescent ingredients, Food Res. Int., 2012, 45, 369-380.

- R. G. Brereton, Chemometrics: Data Analysis for the Laboratory and Chemical Plant, Wiley, Chichester, 2003, 15-19.

- R. D. Snee, Experiments with mixtures, Chemtech, Nov. 1979, 702–710.

- D. Mathieu, J. Nony, R. Phan-Tan-Luu, Nemrodw (V-2007), L.P.R.A.I, Marseille, France, 2007. (www.nemrodw.com).

- A. El Agri, A. Hafnaoui, M. Khouloud, M. Lakehal Senhaji, M. EL Asri, A. Meliani, The use of experimental design methodology in the formulation of a new additive for the dispersion of elemental sulfur in triple superphosphate fertilizer, Mediterr. J. Chem., 2020, 10, 595-607.

- C. P. Santos, T. J. Rato, M. S. Reis, Design of Experiments: A comparison study from the non-expert user's perspective, J. Chemom., 2019, 33, e3087.

- L. Makouki, K. Tarbaoui, S. Glissi, S. Mansouri, H. Hannache, M. Oumam, Applying response surface methodology to optimize the decarbonization process of Timahdit oil shale, Mediterr. J. Chem., 2019, 8, 372-379.

- J. Goupy, L. Creighton, Introduction aux plans d’expériences (3e édition), Dunod, Paris, 2006, 31-202.

- T. Lundstedt, E. Seifert, L. Abramo, B. Thelin, A. Nystrom, J. Pettersen, R. Bergman, Experimental design and optimization, Chemom. Intell. Lab. Syst., 1998, 42, 3–40.

- R. L. Plackett, J. P. Burman, The design of optimum multifactorial experiments, Biometrika, 1946, 33, 305-325.

-Analytical Methods Committee, AMCTB No 55, Experimental design and optimization (4): Plackett–Burman designs, Anal. Methods., 2013, 5, 1901-1903.

- T. D. Pham, N. K. Nguyen, C. M. Tran, M. P. Vuong, Constructing response surface designs with orthogonal quadratic effects using cyclic generators, Chemom. Intell. Lab. Syst., 2020, 198, 103918.

- F. Rossi, V. Mirtchev, Mixture experimental design, statistics for food scientists, Elsevier Inc., San Diego, 2016, 149-167.

- M. A. Bezerra, V. A. Lemos, C. G. Novaes, R.M. de Jesus, H. R. S. Filho, S. A. Araújo, J. P. S. Alves, Application of mixture design in analytical chemistry, Microchem. J., 2020, 152, 104336.

- Z. Jeirani, B. Mohamed Jan, B. Si Ali, I. Mohd. Noor, S. Chun Hwa, W. Saphanuchart, The optimal mixture design of experiments: Alternative method in optimizing the aqueous phase composition of a microemulsion, Chemom. Intell. Lab. Syst., 2012, 112, 1–7.

- M. L. Ntsoane, D. Sivakumar, P. V. Mahajan, Optimisation of O2 and CO2 concentrations to retain quality and prolong shelf life of "shelly" mango fruit using a simplex lattice mixture design, Biosyst. Eng. 2020, 192, 14–23.

- G. G. Marcheafavea, C. D. Tormenaa, E. Daiane Pauli, M. Rakocevic, R. E. Bruns, I. S. Scarminio, Experimental mixture design solvent effects on pigment extraction and antioxidant activity from Coffea arabica L. leaves, Microchem. J., 2019, 146, 713-721.

-Y. Liu, M. Q. Liu, Construction of uniform designs for mixture experiments with complex constraints, Commun. Stat. Theory Methods, 2016, 45, 2172-2180.

- S. Cafaggi, R. Leardi, B. Parodi, G. Caviglioli, G. Bignardi, An example of application of a mixture design with constraints to a pharmaceutical formulation, Chemom. Intell. Lab. Syst., 2003, 65, 139-147.

- D. N. T. Hay, Composition for dust control and improved material handling, U.S. Pat. Appl. 9505965 B2, 2016.

- B. L. Tran, S. Bhattacharja, S. J. Blubaugh, Methods and compositions for dust control and freeze control, U.S. Pat. Appl. 7398935 B2, 2008.

- R. F. Buchholz, D. W. Quinn, Particulate fertilizer dust control, U.S. Pat. Appl. 5360465 A1, 1994.

- F. E. Sexton, J. A. Gratz, K. E. Cox, Combination ammonium sulfate/drift reducing adjuvant and wet bond process for making the same, U.S. Pat. Appl. 6878180 B2, 2005.

- S. D. Brown, R. Tauler, B. Walczak, Experimental Design for Mixture Studies, Comprehensive Chemometrics: Chemical and Biochemical Data Analysis, Elsevier, 2009, 391-449.

- H. Scheffé, Experiments with Mixtures, J. R. Stat. Soc., 1958, 20, 344–360.

- H. Scheffé, The Simplex-Centroid Design for Experiments with Mixtures, J. R. Stat. Soc., 1963, 25, 235–251.

- R. D. Snee, Developing Blending Models for Gasoline and Other Mixtures, Technometrics, 1981, 23, 119–130.

- J. T. Shelton, A. I. Khuri, J. A. Cornell, Selecting Check Points for Testing Lack of Fit in Response Surface Models, Technometrics, 1983, 25,

–365.

- R. Huisman, H. V. Van Kamp, J. W. Weyland, D. A. Doornbos, G. K. Bolhuis, C. F. Lerk, Development and optimization of pharmaceutical formulations using a simplex lattice design, Pharm. Weekblad Sci., 1984, 6, 185–194.

- A. Khaskhoussi, L. Calabrese, H. Bouhamed, A. Kamoun, E. Proverbio, J. Bouaziz, Mixture design approach to optimize the performance of TiO2 modified zirconia/alumina sintered ceramics, Mater. Des., 2018, 137, 1–8.

- G. Geoffrey vining, J. A. Cornell, R. H. Myers, A Graphical Approach for Evaluating Mixture Designs, J. R. Stat. Soc. Ser. C (Appl. Stat.) 1993, 42, 127–138.

DOI: http://dx.doi.org/10.13171/mjc02102221569mls

Refbacks

- There are currently no refbacks.

Copyright (c) 2021 Mediterranean Journal of Chemistry